Forks, trail and rake are hot topics in the world of cycle construction.

Each parameter is affected by the other, and by mixing them up you can produce either a fine handling machine or something with a mind of its own.

As far as road and touring bikes are concerned all of this 'art' is well defined and makers have their preferences and know what works; but here in the cargo arena things are a little less conventional.

With our box bike design, it was therefore necessary to go back to the theory, run some experiments and gather feedback on what worked best.

Also unique to the cargo bike is that fact that significant load is carried by the front wheel. Unlike solo machines there is no risk of clash between the front wheel and the rider's feet and shock to the handlebars is also less of a problem.

Other considerations were the brake type to be used. Discs provide strong progressive braking but require a stiffer/stronger fork because of the increased loads and the fact that only one fork is taking the braking force.

In fact we ran some calculations on comparative braking forces and found that the calliper could exert up to 30 times the load on a fork leg when compared to a standard rim brake.

So what should our fork trail be?

Experiments were used to determine a trail that would produce a decent handling bike and one which was not too affected by increased loads on the front wheel.

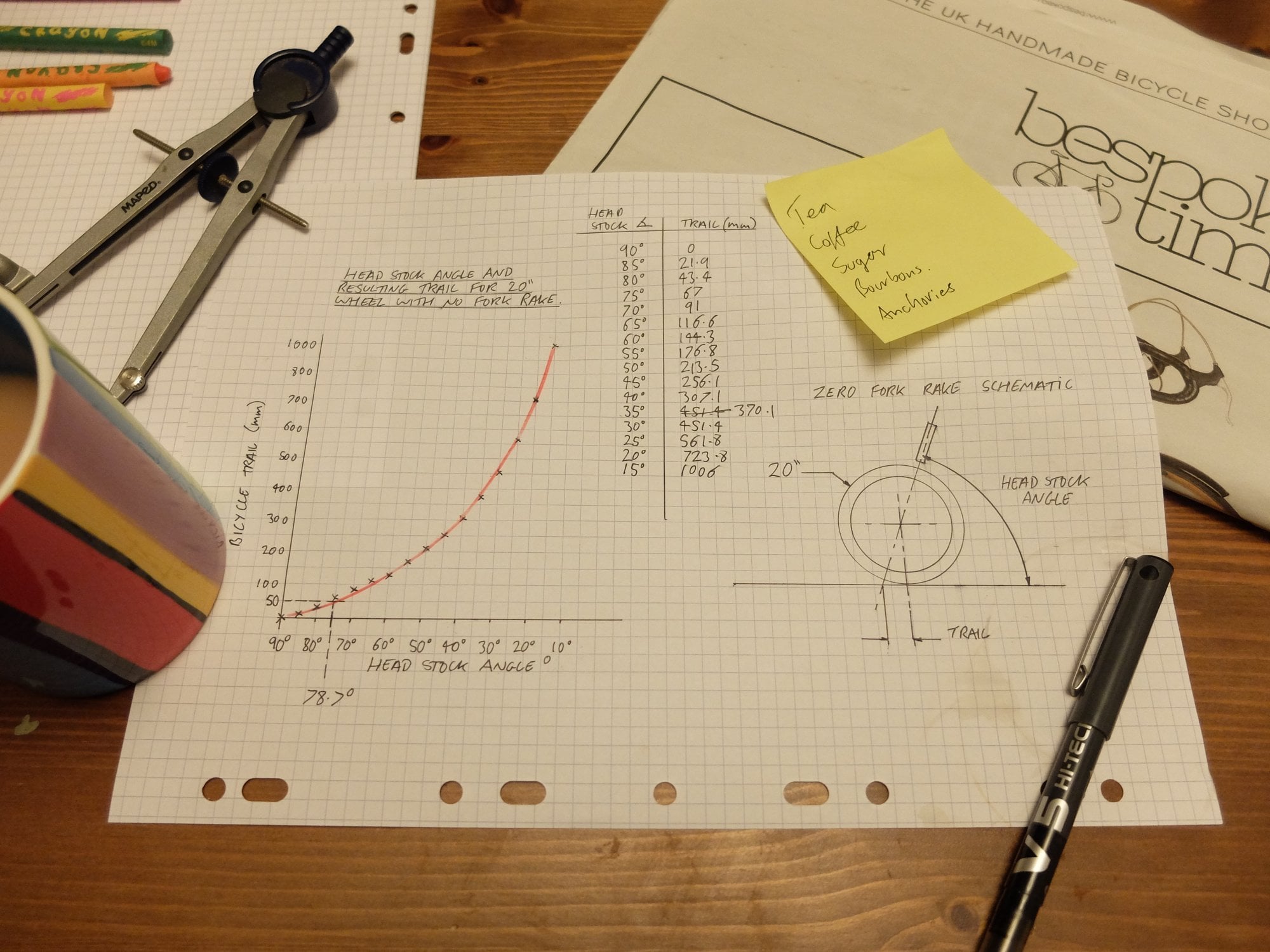

Something worth knowing is that a given trail can be achieved with a straight fork and with no rake, just by getting the correct headstock angle. The graph below shows the relationship between the headstock angle and the resulting trail using a 20" front wheel. Obviously with no angle, there is no trail and much beyond 50 degrees things start to look pretty ridiculous (but don't tell the custom bike boys we said so).

In our case a headstock angle of 78.69 degrees would give 50mm of trail for a straight leg fork.

In reality we decided to add some fork rake to increase clearance between the frame and wheel to allow for mudguard fitment.

We also designed a plate crown fork that should provide the strength we need under braking and under heavy loads.

Out on the road forks have to resist high cycle and low cycle fatigue.

High cycle fatigue is the constant small vibrations, braking forces and steering forces that the bike frequently takes. Low cycle fatigue is the less frequent impact loads such as pot holes, kerbs and incidents involving careless motorists.

Our box bike fork is designed to be strong enough and responsive enough for a light steering effort and predictable handling.